High Precision CNC Machining, Injection Molding & Rapid Prototyping Services - Zetech Mold

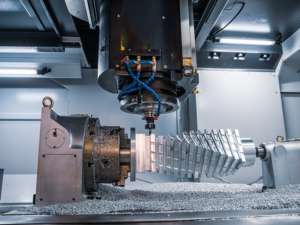

- Offering CNC machining, injection molding, rapid prototyping, and low-volume manufacturing.

- ISO 9001:2015 Certified Manufacturing Facility in China

- Receive Instant Quotes and Complimentary DFM Analysis

- ZE-TECH Mold-Verified Quality Inspections on Every Order

- Access to Over 50 Materials and 20 Finishing Options

ZE-TECH Mold - Take Your Custom Parts Project to the Next Level

Welcome to Zetech Mold, your trusted partner for CNC machining services, injection molding, and rapid prototyping in China.

We specialize in low-volume manufacturing and precision machining to help global customers bring innovative products to life quickly and cost-effectively.

Your best choice:ZE-TECH Mold

⭐Strong professionalism. More than 80% of ZE-TECH employees have more than 10 years of experience in the field of prototype manufacturing, and are experienced masters of CNC machining parts production technology;

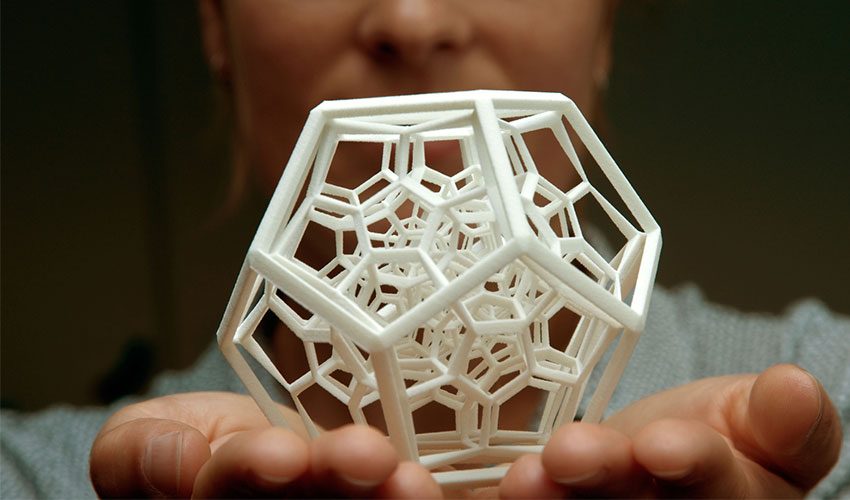

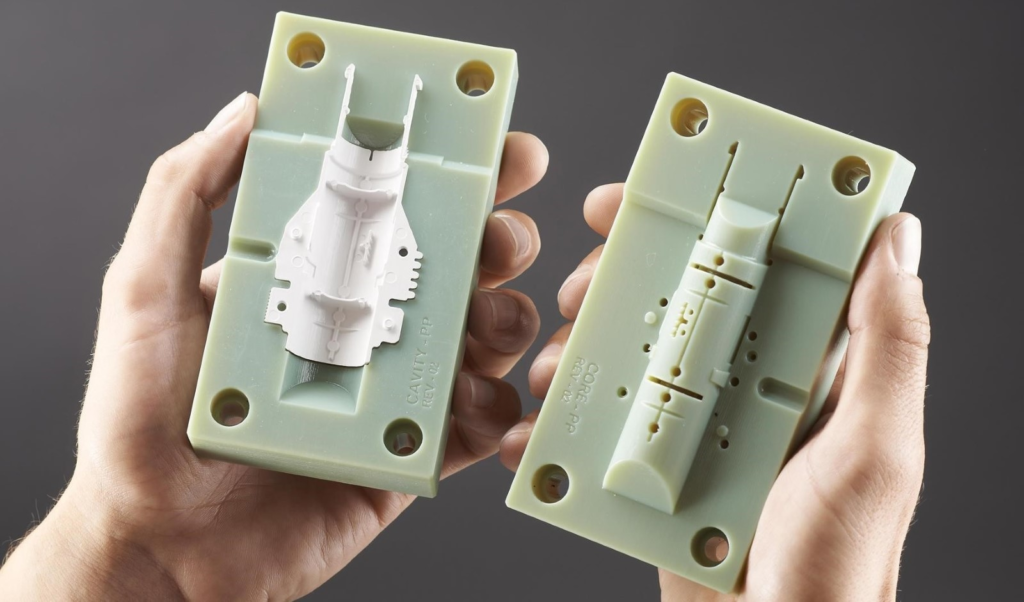

⭐Wide range of services. Our main manufacturing services cover CNC machining, 3D printing, sheet metal manufacturing, vacuum casting, injection molding, etc;

⭐High manufacturing standards. We are an ISO9001/IATF certified supplier, and every step of manufacturing CNC machining parts can meet and exceed the highest industry standards;

⭐Efficient communication. ZE-TECH provides 24/7 online support for your manufacturing projects, allowing you to keep abreast of the CNC manufacturing projects process and progress.

our applications

The progress of industry and society is closely related to machining manufacturing, which greatly improves the precision and production efficiency of products. ZE-TECH serves product development and mass production in various industries.

Medical

Robot

Aerospace

Automotive

our services

With a wide variety of manufacturing capabilities, ZE-TECH support custom parts production on demand and low volume production, and processing parts with complex geometric shape and highly

appearance demands.

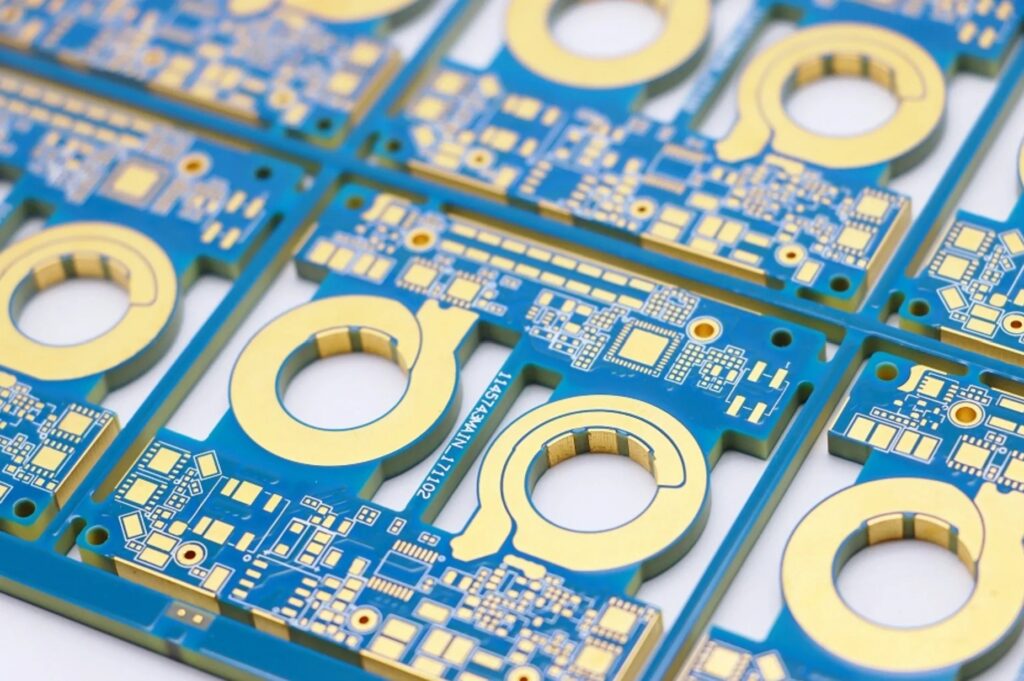

PCBs are the essential foundation of virtually all modern electronic devices. They provide the critical platform for mounting and interconnecting electronic components (like chips, resistors, and capacitors) using conductive pathways etched onto a non-conductive substrate.

PCBA (Printed Circuit Board Assembly) represents the fully assembled and operational stage of a PCB. It transforms a bare circuit board into a functional electronic unit by mounting, soldering, and integrating all necessary components (such as ICs, resistors, capacitors, connectors) onto the PCB.

15years of rapid prototyping experience

Cooperation with more than 50 foreign companies

Over 10,000 projects completed

Manufactured 200,000+ prototypes

why choose us

We Promise:Professional Engineering Guidance;Provides 24/7 online support;High-quality & Fast Lead-time;98% On time delivery rate;Full after-sales service.

we have good order procedure

This will provide you with more reliable products, faster services, more consistent experiences, less troubles and greater security.

we have good certification system

This will provide you with reliability assurance, help you reduce decision-making costs, and safeguard your rights and interests.

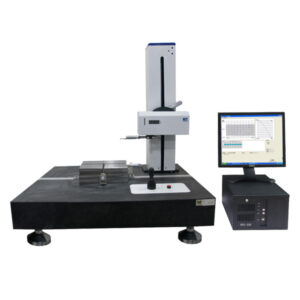

we have good QC system

This will provide you with a better and ensure every processing to check in higher level ,can enhance the core experience of your products .

we have good delivery and package

This will provide you with a more reliable transportation experience and ensure that you have no worries throughout the process.

Our Clients!

“ZE-TECH MOLD has been an incredible manufacturing partner. Their CNC machining quality is top-notch, communication is always fast and clear, and they consistently meet tight deadlines. Highly recommended for any prototyping or low-volume project!”

“We’ve worked with ZE-TECH for several projects — CNC parts, 3D printed enclosures, even PCBA. Every time, the results exceeded expectations. It’s rare to find a supplier that’s fast, flexible, and quality-focused all at once.”

“Reliable, responsive, and detail-oriented — that’s why we trust ZE-TECH MOLD. From the first quote to final delivery, the process was smooth and professional. Their team even offered helpful DFM suggestions before production.”

our latest blog posts

Seven Most Common Manufacturing Materials: ABS, PA, PP, POM, PC, PMMA, and Aluminum — Properties, Machining Methods, and Finishing Options

Material selection is one of the most critical steps in...

Read MorePrecision Measurement in Modern Manufacturing: Understanding CMM, Vision Measuring Machines & Other Key Inspection Tools

In modern manufacturing, precision is no longer a competitive advantage—it’s...

Read MoreEssential CNC Machine Setup & Production Checklist for High-Precision Manufacturing

In CNC manufacturing, precision relies not only on advanced equipment...

Read MoreA Complete Guide to Silicone Vacuum Casting (Urethane Casting)

Introduction Silicone vacuum casting—also known as urethane casting or silicone...

Read Morethanks for reading

Contact With Us Today!

The most professional team of ZE-TECH mold will help you realize your dreams.